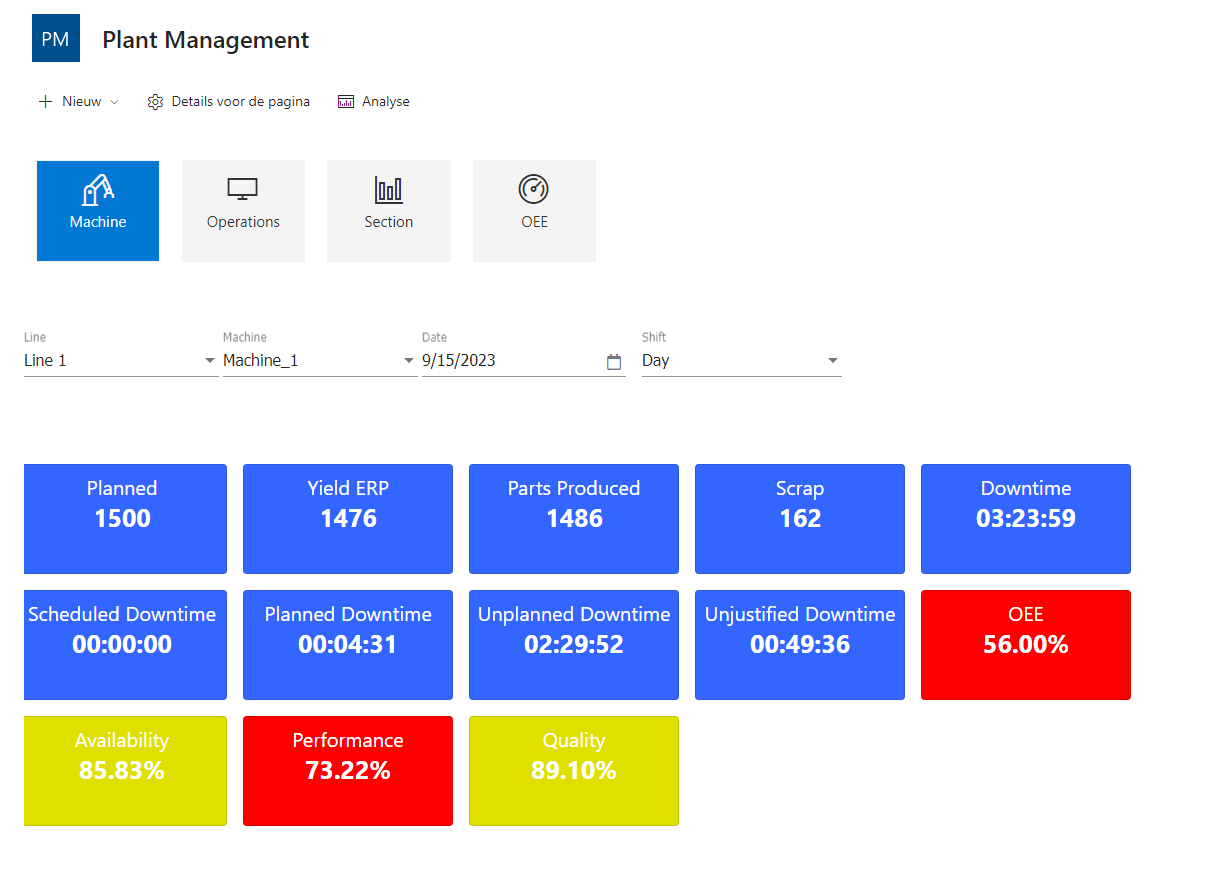

Advanced Filtering Options

Filter machines by line, machine, date, and shift to access precise data easily.

Real-time Dynamic KPI Tiles

Interactive KPI tiles in the digital workspace display real-time performance metrics for selected machines, shifts, or days.

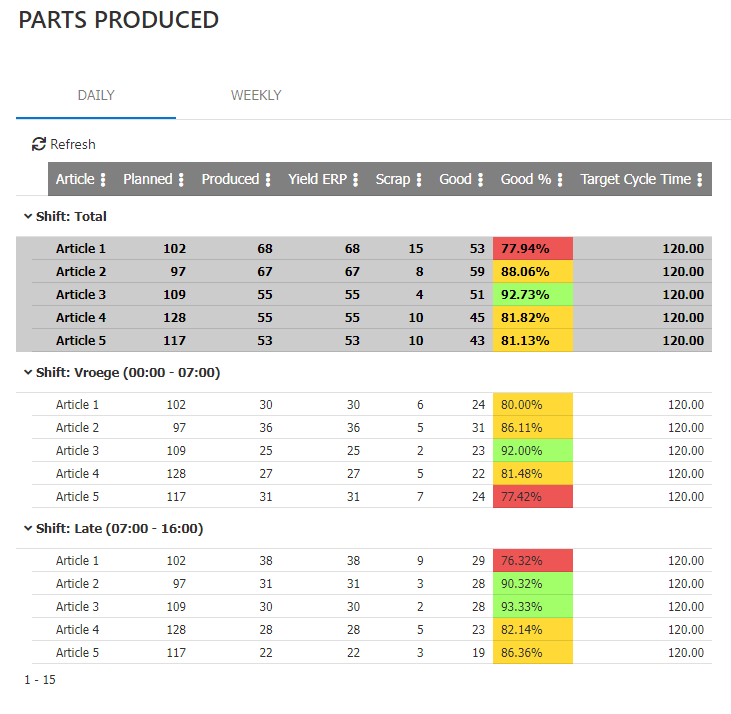

Comprehensive Data Views

Analyze daily and weekly machine performance, including production targets, scrap rates, and machine stops.

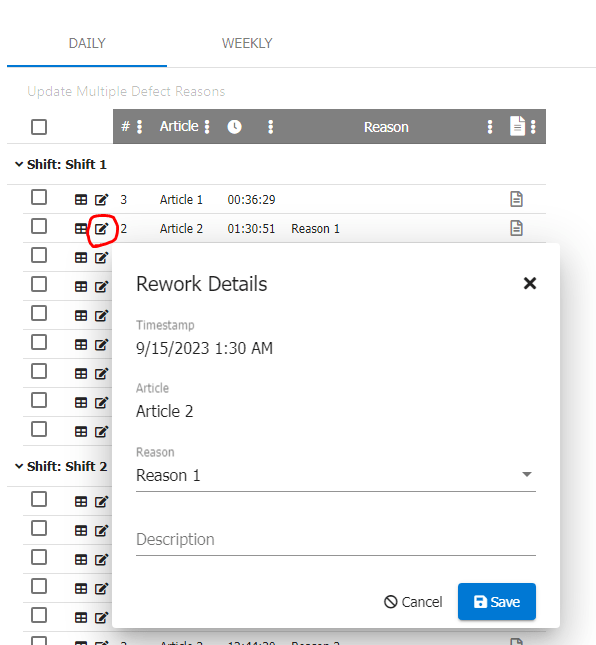

Detailed Scrap Analysis

View scrap data by time, shift, and reason, with options for updating reasons and descriptions.

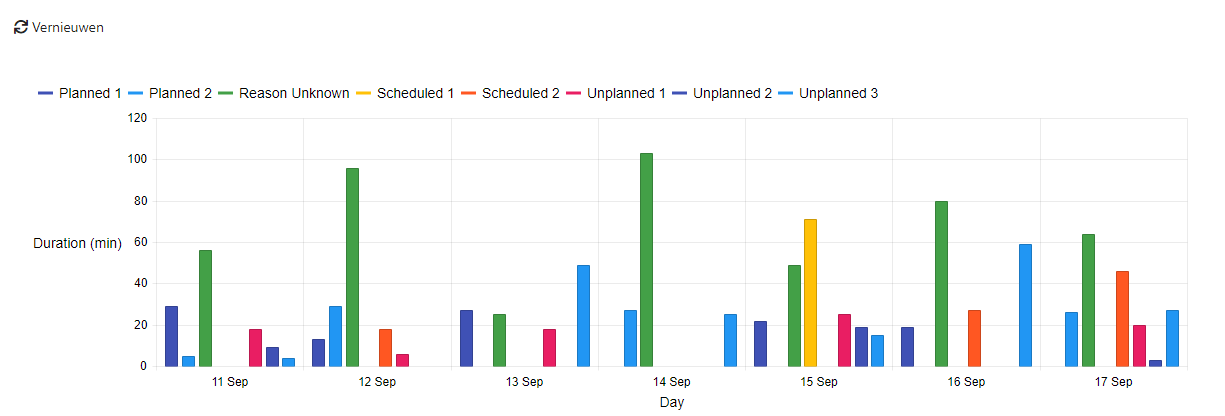

Stops and Downtime Management

Detailed views of machine stops, including downtime reasons and descriptions.

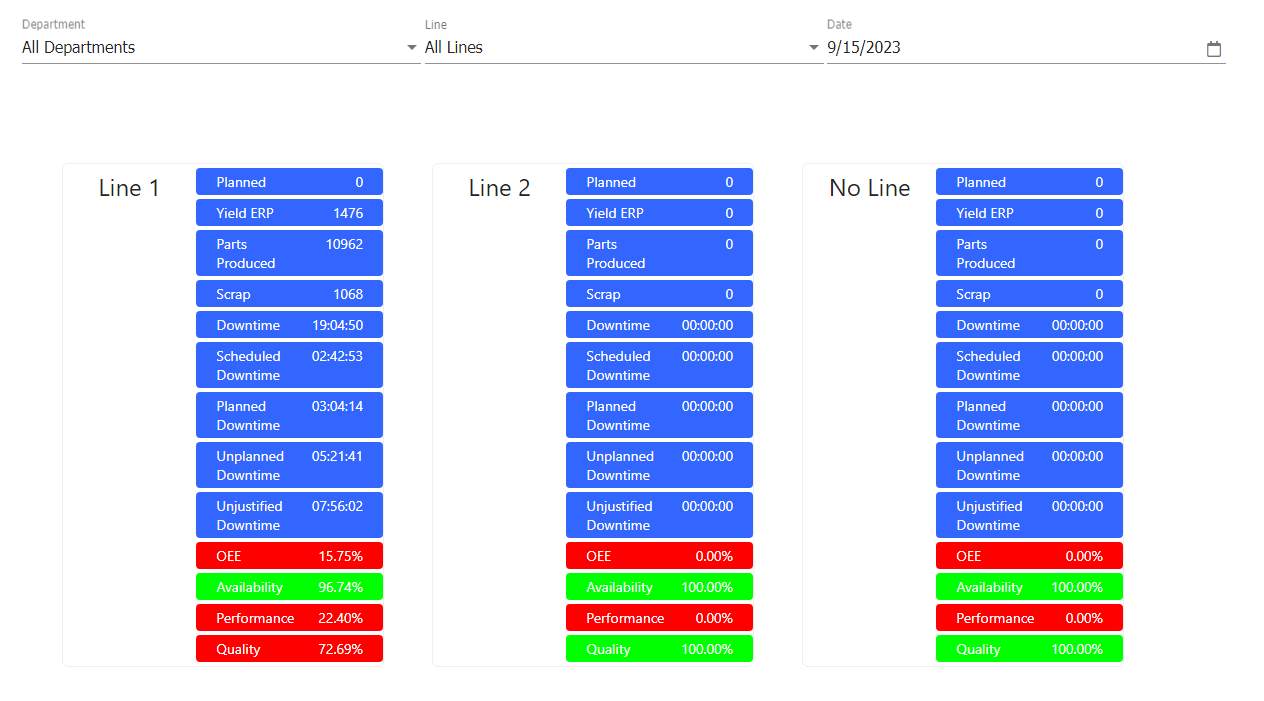

OEE Dashboard

Monitor OEE metrics and components, including availability, performance, and quality, with trend analysis.

Key benefits

More features

Entity Hierarchy

The solution has a hierarchy from plants to machines, to enhance organization and efficiency. This structure ensures precise data management, helping users define plants, departments, lines, and machines, making operations more streamlined and improving the overall clarity of production processes for effective monitoring.

Thresholds

Implement threshold settings to customize the appearance of KPIs based on specific values. This provides immediate visual feedback, highlighting performance variations with color-coded indicators. It helps users identify areas that require attention, ensuring timely interventions and optimal operational performance.

Tracking

Assign and categorize reasons for downtime and scrap, offering insights into inefficiencies. This allows users to analyze the causes of production disruptions, thus supporting targeted improvements and strategic decisions to minimize waste and enhance productivity.

KPI Library

Access a wide range of predefined Key Performance Indicators (KPIs) to track production metrics. This comprehensive library allows for in-depth performance analysis, helping users monitor, measure, and optimize manufacturing processes to align with operational goals and boost efficiency.

Some impressions

Pidpa

We can work with the tool ourselves. That’s important to us because next to autonomy, it also offers us more speed and flexibility

Niko

When using our new digital workspace our employees have access to various real-time information at the right time

Still interested? Great!

Are you ready to see how our plant management software works in real time or get a personalized quote for our digitalization software? Feel free to request a quote or schedule a demo with our team. We are here to help you find the perfect plant management or quality control software solution!