About Krohne

Krohne is a leading manufacturer of flowmeters, a specialized equipment for measuring liquids and gas flows. Krohne’s products are used for different types of applications and are used by, for example, water companies, nuclear power plants, the oil industry, pharmacy, mining and in many other sectors and companies. Due to the large variety in use, the customer often defines his own specifications. For example, the customer can decide on the size of a pipe, the type of meter, the used materials, the specific configuration and much more. This results in a very wide range of possibilities on the production line.

You can only complete the sales puzzle if you control all production pieces

In parallel with Krohne’s wide variety of production possibilities, the information landscape in which all data relating to sales and production are processed is also very fragmented. In order to increase the efficiency of the production process and to optimize the service to its customers, Krohne therefore looked for a solution to optimize the cooperation and information flow between sales and production.

The objective of the project is to make the expectations that are linked to a sales order transparent for all stakeholders in the chain. Via a digital collaboration platform, Krohne wants to give all the involved departments a clear insight into the status of production of every single part. From shop floor to top floor. As soon as there is an issue on the production floor (e.g. a line stop, a material shortage, a resource that is late), the priorities and decision-making can be adjusted in real time at both production and sales level. This is possible because all information is made transparent in a single integrated platform. The ultimate goal is to involve the customer directly into this collaboration platform whenever there is a deviation or lack of clarity.

Until recently, the flow of information still passed through Excel sheets, e-mails and paper. Consequently, for every small change in the chain, the latest information had to be gathered from several sources. This wasted precious time because people were busy looking for information and analyzing the latest status or change. This had an impact on the speed of decision-making and collaboration.

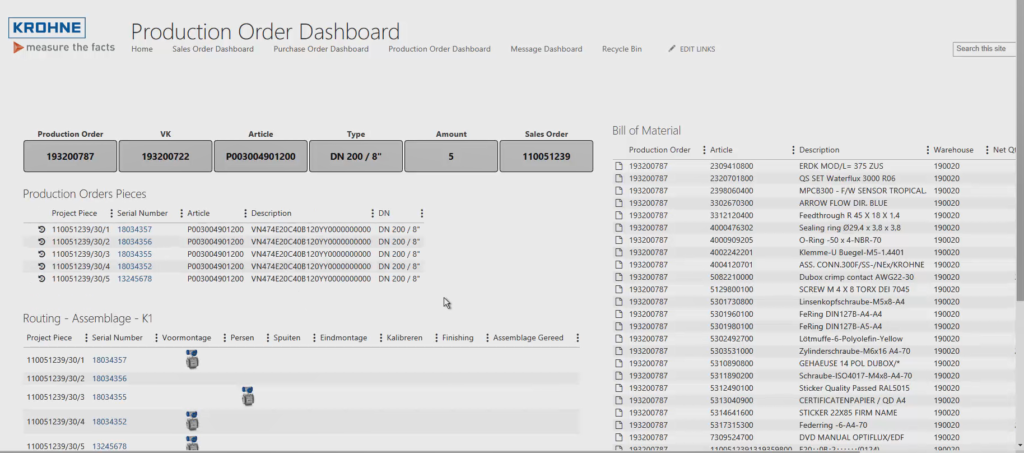

Krohne pays a lot of attention to customer satisfaction. In this context, we consider the timely delivery of all pieces of a sales order as the complete puzzle. In order to complete this puzzle and thus meet customer expectations, it is necessary for the organization to have all production items (or pieces or parts) under control. Where today the ERP ensures the creation of production orders on a batch level, effective single piece follow-up is not evident. The link between the production order and the final sales order can only be made through a complex search in the ERP system.

By introducing a One-Piece-Flow follow-up, Krohne can manage the production process more flexibly for everyone in the chain. This allows the company to improve the efficiency of the production process. On the other hand, when we look at the relationship between Krohne and its customers, the larger whole becomes more transparent. As soon as one piece in the One-Piece-Flow can make sure that the customer’s expectations cannot be fulfilled, the digital platform automatically gives a notification that is visible to both the production operators and the sales organization. This information sharing throughout the chain facilitates much faster decision-making, which means that timely adjustments can be made depending on priorities and expectations.

In reality, a small change in the production process can affect the larger picture. For example, a resource that is too late, a non-confirmation of a component, a line stop, etc., can all affect the final delivery. Thanks to the analysis of all information flows, Krohne can now map all the pieces of the puzzle that are necessary to complete the puzzle. Responding quickly and adequately to any deviation can greatly increase lead times, efficiency and the reliability of deliveries.

Planned situation vs actual situation

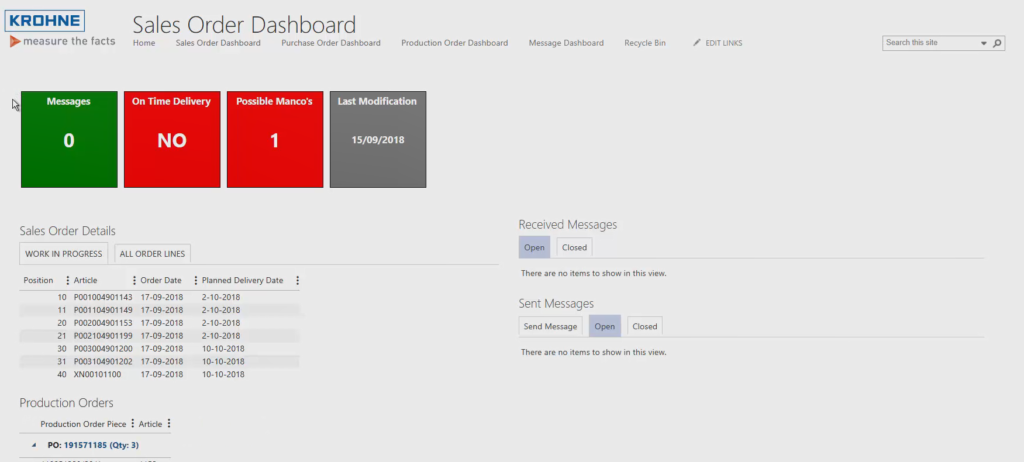

Thanks to graphical displays, you can trace up production status up to single production part level. We consider each individual product (‘piece’ or ‘part’) as a case. Each case contains all linked sales order data, production order data, drawings, quality information, supplier details, and so on. All this information comes from different underlying systems and is brought together in one digital overview.

Integrated portals give Krohne a clear insight into the planned situation. The platform enable the company to compare this in real-time with the actual situation on the production line. This gives Krohne the opportunity to intervene immediately as soon as the planning of an order is in danger. In order to create this platform, no systems or applications were replaced. It is thanks to the combination of the active systems (data) and the right people (decisions) that the improvement is ensured.

When a problem is identified in the production process and the planning might be affected, a signal is automatically sent through the entire stakeholder chain. Thanks to the platform, all those involved look at the same version of the truth. This has tremendous value. The operator receives a warning for the affected production orders, the sales organization is notified of the linked sales orders and in the future, even the customer will directly be invited to the platform to discuss the situation in real-time. This way of transparent collaboration offers the possibility to discuss whether to order alternative goods, to do partial deliveries or to change planning.

Efficient collaboration between all stakeholders

In other words, the entire chain is controlled based on events. Based on data in the ERP system, the priority of the orders in the queue can be planned or adjusted in real-time. This allows Krohne to validate the delivery time, stock availability, outsourcing and possible non-confirmations at any time. Every change in the chain can then immediately influence the priorities in the production facility and become a reason to inform the sales organization and the customer.

Thanks to this new way of working, Krohne can cooperate more efficiently with its suppliers and customers. This allows them to act immediately in any situation without using e-mails, phone calls and searching for information that is distributed via several information islands.

The speed of communication has increased enormously because all stakeholders look at the same information in the same platform. From the shop floor right up to customer level, everyone works with a single real-time version of the truth. The aim of Krohne is to improve the throughput times and the production process with as much as 40% thanks to the current digitization project. Moreover, thanks to horizontal integration in the chain, Krohne expects to give a strong boost to the relationship with its suppliers and customers.

The foundations for a smart factory

The current project ensures that Krohne becomes even faster and more efficient. But the company is already preparing for the future. This means that Krohne also wants to make its factory smarter. The One-Piece-Flow follow-up is a first step towards the digital shadow of the production piece. In the digital shadow, process information can be added in addition to logistic data and production data. The digital shadow or the digital representation of the piece forms the basis to grow to a Smart Factory.

Would you like to know the full story? Then register for free for the knowledge events on 13 November at OMC Turnhout or on 22 November at Krohne Dordrecht, where Krohne will give an inspiring presentation on this topic!